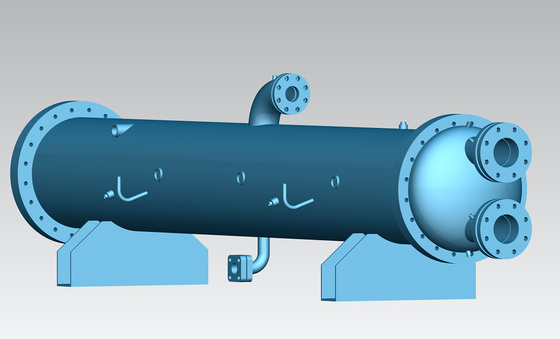

The housing of the chiller is designed with the three-dimensional sheet-metal software Solidworks and processed by the imported precision-numerical-control sheet-metal equipment, and the housing surface is well treated with the environmental electrostatic powder coating, which makes the chiller be elegant and durable. The condenser adopts the thickened corrugated window-opening aluminum finned sheet and copper tube, which makes high efficiency on heat exchange, environmental and power-saving.

The constant temperature cold and hot water machine is specially designed for polyurethane foaming and phenolic foaming. It is used to keep the water temperature of A B tank jacket so that the foaming raw materials can be kept at the required temperature. The special constant temperature controller “Jingchuang” is adopted to control heating or refrigeration automatically according to the set required water temperature, which has high control accuracy and simplicity of operation. Selected famous brand compressors (Panasonic, Daikin, Copeland) and refrigeration electronic control components (Danfoss, Emerson, Siemens, etc.) guarantee the products with high quality.

Application:

Temperature control of tank for polyurethane foaming, phenolic foaming, EPS foaming and other foaming equipments.

Technical Specifications:

1. Model number specification: e.g. DC-CH10A-D, “DC” indicates Doco company code, “CH” indicates constant temperature cold and hot water machine, “10” indicates 10 horsepower, “D” indicates dual system with two compressors, “T” indicates three compressors, “F” indicates four compressors.

2. *Compressor power: *2indicates two compressors working and two independent refrigerating systems.

3. Refrigerating capacity parameter basis: the temperature of inlet and outlet chilled water is 12℃/ 7 ℃ and the temperature of inlet and outlet cooling air is 30℃ / 35℃.

4. Working ranges: the temperature range of chilling water is from 5℃ to 40℃, the temperature difference between inlet and outlet chilling water is from 3℃ to 8℃, the ambient temperature can not be higher than 40℃, and the high- temperature model should be selected when the ambient temperature is higher than 40℃.

5. We reserve the right to revise the above information without prior notice.

Constant temperature cold and hot water machine applied in polyurethane PU foaming equipment

Constant temperature cold and hot water machine applied in phenolic PF foaming equipment

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!