Performance:

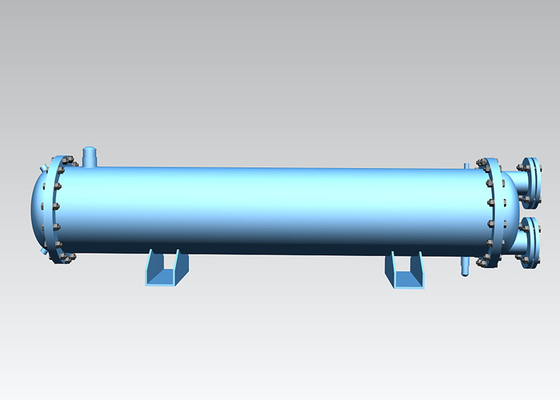

Film Chiller is specially designed for cooling plastic film blowing machine. The working principle is as follows: The chiller refrigerates through the compressor, the indoor ambient air should be cooled from 40-45 ℃ to 10-15℃ through the built-in high efficiency copper tube heat exchanger, and then high-pressure centrifugal blower sends low-temperature air to the inner and outer air rings of the film blowing machine through air duct in order to cooling the film bubble which has just been blown out from the die head, the film bubble can be cooled quickly, all which improves the thickness uniformity of the film, increases the transparency and brightness, accelerates the film setting, enhances the film physical properties and increases output by more than 20-30%.

The film cooling machine has a strong ability to dehumidify the air which has a large amount of condensate water when the air is cooled rapidly, which keeps the sending out cold air dry and being low temperature, all this improves the quality of the film.

Application:

Internal and external cold film blowing unit, three-layer co-extrusion film blowing unit, multi-layer co-extrusion film blow molding unit, etc.

Technical Specifications:

1, “Model”description:e.g. DC-BF10W-D,“DC" is Doco company code, "BF"indicates film cooling machine, "10"indicates horsepower 10, "A" indicates air cooling, "W" indicates the water-cooled type, "D"I indicates dual system with two compressors, "T" indicates three compressors.

2, * Marked compressor power * 2 stands for two compressors working for refrigeration and two separate refrigeration systems for the air cooler.

3, The refrigeration parameters are based on the inlet and outlet air temperature 25℃ / 10℃and the condensation temperature 35℃.

4, Working ranges: chiller air outlet temperature is 5-20℃ with the ambient temperature less than 40℃.

5, We reserve the right to change the above parameters or dimensions without prior notice.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!