Performance:

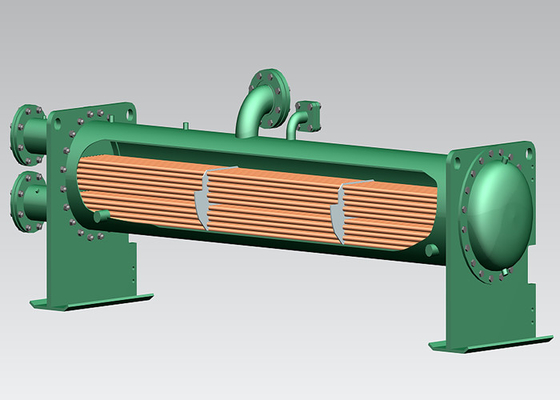

The housing of the chiller is designed with the three-dimensional sheet-metal software Solidworks and processed by the imported precision-numerical-control sheet-metal equipment, and the shell surface is well treated with the environmental electrostatic powder coating, which makes the chiller be elegant and durable. The condenser adopts the thickened corrugated window-opening aluminum fin with copper tubing, which makes high efficiency on heat exchange, environmental and power-saving.

Built-in high and low voltage, overload, delay, flow and other multiple protection devices ensure the equipment operation more stable. The world famous brand compressors (Panasonic, Daikin, Copeland) and refrigeration electronic control components (Danfoss, Emerson, Siemens, etc.) are selected for the equipments. The general model control accuracy is ±1℃ and the special model can reach ±0.5℃.

Multiple refrigeration circuits can be set up and each circuit can run separately, which meets the demand of variable load, favours power saving, improves the safety and stability of equipment operation, and satisfies the severe requirements for temperature in various industrial production. The normal temperature model is 5-25℃ and the low temperature model is from -25℃ to -5℃. Non-standard models can be customized based on customers’ requirements.

Application:

The air cooled chillers are widely used in injection mold, laser marking welding equipment, vacuum coating machine, packaging machinery, semiconductor equipment, welding machine electrode, plasma cutting machine, spindle cooling of PCB drilling machine, etc. to protect the precision equipments and improve production efficiency.

Technical Specifications:

1. Model number specification: e.g. DC-C10A-D, “DC” indicates Doco company code, “C” indicates chiller, “10” indicates 10 horsepower, “A” indicates air cooled chiller, “D” indicates dual system with two compressors, “T” indicates three compressors, “F” indicates four compressors.

2. *Compressor power: *2indicates two compressors working and two independent refrigerating systems.

3. Refrigerating capacity parameter basis: the temperature of inlet and outlet chilled water is 12℃ / 7℃ and the temperature of inlet and outlet cooling air is 30 ℃ / 35℃.

4. Working ranges: the temperature range of chilling water is from 5℃ to 35℃, the temperature difference between inlet and outlet chilling water is from 3℃ to 8℃, the ambient temperature can not be higher than 40℃, and the high-temperature model should be selected when the ambient temperature is higher than 40℃.

5. We reserve the right to revise the above information without prior notice.

The Applications of Air Cooled Chillers

The Application of Chillers in Vacuum Ion Coating Equipment

The Application of Chillers in Vacuum Casting Equipment

The Application of Chillers in Bearing Steel Ball Industry

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!