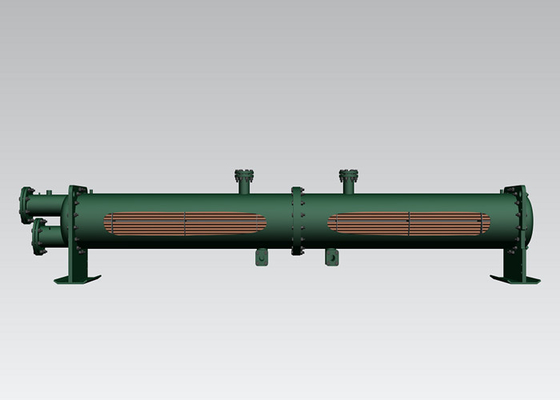

The housing of the oil chiller is designed by the 3D sheet metal software and machined by CNC sheet metal equipment of Germany with environmental electrostatic spraying, which makes the oil chiller solid, wearing well and elegant. The condenser of the oil chiller is made of thickening copper tubing and corrugated aluminum fin, which makes the oil chiller with high heat exchange efficiency and saving electricity. The world famous brand compressors, such as Panasonic, Dakin, Copeland etc., are used in oil chillers and the electric controlling components for refrigeration are also famous brands, such as Danfoss, Emerson, Siemens etc. Necessary electrical and mechanical safety protection devices, such as high pressure protection, low pressure protection, overload protection, delay protection, overheat protection etc., are provided for the oil chillers, which ensure the stable operation of the equipments.

The oil chiller is aimed at reducing the oil temperature to prevent oil from degradation, oxidation or evaporation, keeping the oil viscosity and stabilizing the oil pressure to avoid oil shocking. All these prolong the service life of equipments or cutters and improve the machining accuracy of machine tool.

Specially, the oil chiller has a separate oil pump circulation system, through which the oil is sucked into the fuel tank, cooled by oil chiller and then sent back to fuel tank. That keeps the oil in the fuel tank constant at the setting temperature.

Application:

The oil chillers are widely used in industries: Large Hydraulic System, Hydraulic Machine Tool, CNC Machining Center, Milling Machines, Grinding Machines, Four-Column Punching Machines, Engraving Machines, the Hydraulic Pressure Station or Lubricating System of all kinds of machines.

Technical Specifications:

1. Model number specification:e.g. HN-YL210P-D, “HN” indicates company code, “YL” indicates oil chiller, “210” indicates refrigerating capacity 210KW, “P” indicates built-in pump, “D” indicates dual system ( two compressors), “T” indicates three compressors, “F” indicates four compressors.

2. * Compressor Power: *2 indicates two compressors working and two separate cooling system.

3. Nominal cooling capacity calculated according to:Ambient temperature: 35℃. Oil inlet flow temperature: 35℃. Oil outlet flow temperature: 30℃. Oils: ISO Vg46.

4. The oil suction inlet must be connected with rigid tube, and it's necessary to install filter. Meanwhile, it's prohibited to install valve on the oil outlet.

5. The length of oil suction tube should not be more than 1.5meters; Otherwise, the diameter of oil suction inlet must be increased.

6. Working range: Oil temperature ranges from 15℃ to 50℃. Temperature difference between inlet and outlet oil is from 3℃ to 8℃. It is better to run the oil chiller while the ambient temperature at or below 42℃; Otherwise it's necessary to use high temperature models.

7. We reserve the right to revise the above information without prior notice.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!